What is Compact HPL?

The embedded laminates are manufactured with an inner core of celluloid fibers impregnated with special thermosetting resins. These resins and special heat and pressure cycles impart the laminate’s load-bearing properties, which are resistant to a wide range of weather and chemical agents for use in indoor and outdoor weather conditions. High values of flexural strength and tensile strength ensure that these strips are suitable for saw cutting, drilling, machining and perforating as per requirement.

Compact HPL manufacturing

The word HPL means High Pressure Lamination in English and is an abbreviation for High Pressure Laminate, which is the process that embedded HPL is exposed to during the manufacturing process. The manufacturing process is carried out by coating layers of kraft paper on both sides with phenolic, an environmentally friendly material that resists acids, alkalis, fires, humidity and collisions. Then a layer of laminate is added to the kraft layers at the top and bottom, which is scratch-resistant and easy to clean. The pressing process takes place under pressure of 1430 psi and temperatures of 150°C. Compact HPL panels can be manufactured in an infinite number of different colors and thicknesses, starting from 2.5 mm up to 30 mm.

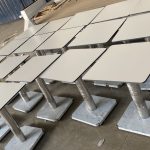

Uses of compact HPL

- Bathroom partitions

- Office and bathroom doors

- Kitchens

- Tablets and surfaces of tables and desks

- Office partitions in stores and companies

- Urinal dividers

- Sprays for restaurants and hotels

- Dressing room dividers and bathroom dividers

- Tablets and surfaces of laboratory and hospital units

- Lockers lockers for gyms and clubs

Features of Compact HPL

- Easy to disassemble and install without requiring much effort

- It withstands high temperatures due to its resistance to fire and is therefore considered a very safe material for use in industrial and commercial fields

- It is resistant to water and humidity and is therefore used in the manufacture of bathroom partitions and bathroom dividers

- It is resistant to weather and sun factors, thanks to its resistance to water, heat, and fire

- It is resistant to bacteria and acids, which is why Compact HPL is a distinctive choice for use in bathroom partitions and health fields such as laboratories and hospitals.

- Compact HPL is easy to clean

- Compact HPL is non-toxic, non-polluting and completely hygienic

Samples

Accessories

Gold Stone Company provided the finest types of imported 304 stainless steel, of Chinese origin, produced by the XDF factory.

Neon accessories and Egyptian accessories are also available

Features of stainless steel 304 XDF accessories

• Accessories that are not affected by water at all

• Resistant to weather factors and temperatures

• She is distinguished by her gratitude and ability to withstand pressure